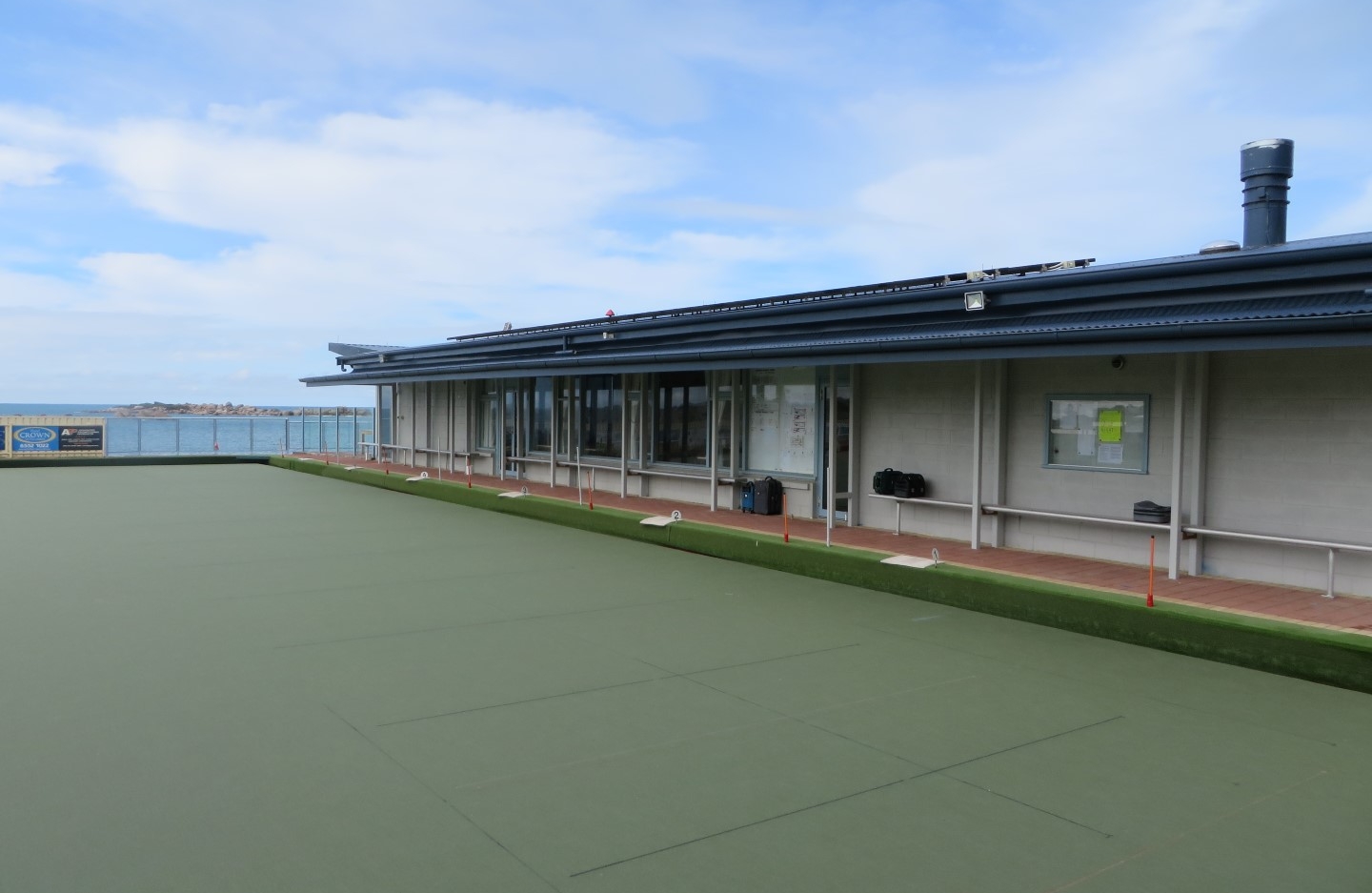

Now, thanks to Orrcon Steel and its revolutionary pre-coated MAXI-TUBE®, the only thing rusty at the Port Elliot Bowling Club are some of its members’ bowling skills.

Orrcon Steel supplied the bowling club with 75sqx4mm, 125x75x5mm, 150x50x5mm, all in 8m lengths and equating to approximately 1000kg in total of MAXI-TUBE®.

Port Elliot and the surrounding regions are infamous for being some of the most corrosive coastal environments in Australia, and are a huge challenge for coated steel products. For this reason, the region is specially mentioned in AS2312 under the atmospheric corrosiveness category section.

According to Orrcon Steel National Sales and Marketing Manager, Distribution, Lester Kirkwood, “The corrosion resistant alloy coating of MAXITUBE® is comprised of zinc, aluminium, and magnesium, it has good galvanic protection in aggressive environments and is compliant to AS1397. It provides very good paint and powder coat adhesion with a high quality surface finish.”

The additional paint coating on the welded connections and over the entire steel section of the Port Elliott Bowling Club structure provides further protection, while also acting as an architectural feature. “When it comes to building infrastructure, remote housing and shade structures in semi and severe marine aggressive environments, the galvanic protection, aesthetics and long term durability of MAXI-TUBE®’s ZM275 coating provides a well-balanced solution,” said Kirkwood.

Project: Port Elliot Bowling Club

Location: Fleurieu Peninsula, South Australia

Orrcon Steel Products: MAXI-TUBE® – 75sqx4mm, 125x75x5mm and 150x50x5mm Completed August 2014

Water Conservation and Reuse

Water scarcity is a critical global concern, with resource-intensive sectors like steel production playing a central role in exacerbating water consumption. Fabrik has taken decisive action to address this issue by prioritizing water conservation. The company has acknowledged the imperative to curtail its reliance on freshwater sources and safeguard the integrity of local water resources.

Fabrik has embarked on a path of innovation by deploying cutting-edge water treatment technologies that enable the recycling and reuse of water throughout its manufacturing operations. This forward-thinking strategy has substantially reduced water consumption and has concurrently diminished effluent discharge. As a result, the company has made significant strides in preserving nearby water bodies and ecosystems.