Build With Confidence

Orrcon Steel Manufacturing’s SSA Level 1 Certification and EPD Credential help you and your customers meet Green Star targets and sustainability benchmarks with documentation ready for submission.Why the Certification And Credential

Matter for Projects?

Contribute to Green Star Ratings

Qualify for Government and Infrastructure Projects

Enhance Customer Appeal

Access Reliable, Verified Environmental Data

Support Streamlining of Compliance and Documentation

Support Your Sustainability Story

Earning Green Star points

Green Star Responsible Products Framework – How it works

The construction sector is increasingly adopting sustainable building practices, driven by both environmental concerns and regulatory requirements. The Green Star Responsible Products Framework recognises initiatives that a product or manufacturer can comply with to contribute towards a Green Star certification. Products may contribute to a project’s Green Star rating through the Responsible Products credits, provided proof of certification is included in the Green Star submission.

A Responsible Product Value (RPV):

The ‘score’ given to an initiative after assessment against the Responsible Products Guidelines.A ‘Responsible Product’:

A product that has been awarded a RPV by the Green Building Council of Australia through a recognised certification initiative.

Orrcon Steel Manufacturing Products Now Meet Multiple Green Star Recognised Standards

Steel ResponsibleSteel™ site certification

Sourcing steel from BlueScope, a Verified SSA Supplier and ResponsibleSteel™ certified Site, can provide a further 10 RPV.

EPD

EPDs include a verified embodied carbon footprint and assist in the following Green Star – Buildings credits with an RPV of 5.

SSA LEVEL 1

Certification to SSA level 1 meets the requirements to gain a responsible product value (RPV) of 4 under the ‘Responsible’ category in the Green Star Buildings rating tool.

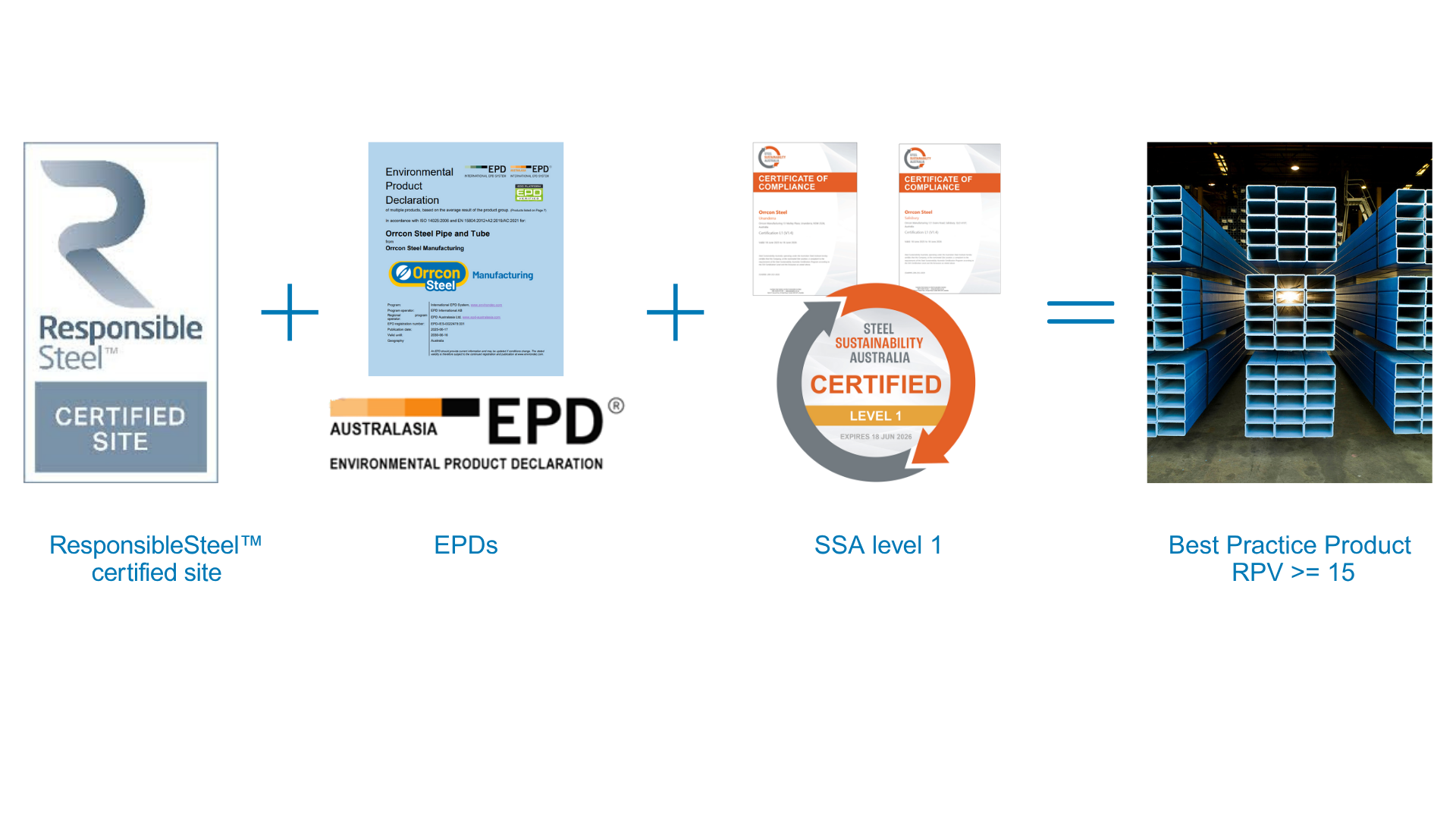

A combination of ResponsibleSteel, Product-Specific EPD and SSA Level 1 under GBCA’s RPV methodology results in an RPV equivalent to a Best Practice product (≥15).

Orrcon Steel Manufacturing & The Green Star Scheme

What Our Steel Distributors Are Saying:

❝ We have evidenced significant increases for requests for Sustainable Steel Product for new projects compliant to Green Building Council Australia. With Orrcon Steel Manufacturing’s certification and credential, we’ve been able to continue to support our customer demands. We welcome Orrcon Steel Manufacturing’s support in our sustainability journey.❞

GM, Steel Distributor Partner, Australia

Partnering with us

helps you demonstrate due diligence and a clear commitment to ethical sourcing and environmental performance.

Frequently Asked Questions

Download our quick guide for a fast, straightforward overview of these certification and credential and how they support Green Star project requirements or book a one-on-one session with our expert to discuss your project in more detail.

What is SSA Level 1 Certification?

SSA Level 1 Certification is the entry-level tier of the Steel Sustainability Australia certification program. It verifies that a steel supplier meets recommended practice standards in governance, environmental management, and occupational health and safety (OHS), and that the majority of their steel feedstock is sourced from a responsible steel manufacturer or producer.

What are the key requirements for Level 1 Certification?

To achieve Level 1, a business must:

- Demonstrate recommended practice governance and OHS management against the Green Building Council of Australia’s (GBCA) Responsible Products Framework

- Show compliance with environmental management criteria

- Ensure that the majority of steel feedstock is sourced from a responsible producer

What are the benefits of being SSA Level 1 certified?

- Recognition under the Green Building Council of Australia’s (GBCA) Responsible Products Framework

- Contribution to Green Star rating points for construction projects

- Enhanced customer credibility and sustainability credentials

- Alignment with ESG expectations in the construction and infrastructure sectors

Where can I get help or more information about SSA?

Steel Sustainability Australia (SSA) is a national certification program that promotes and verifies sustainable practices across the entire steel supply chain in Australia. It was developed by the Australian Steel Institute (ASI) and supersedes the earlier Environmental Sustainability Charter (ESC).

You can contact SSA directly at ssa@steel.org.au or visit their official website for resources, guides, and support.

What is an EPD?

An EPD is a standardized document (based on ISO 14025 and EN 15804) that communicates the environmental performance of a product, using Life Cycle Assessment (LCA) data.

Further details can be found at EPD Australasia EPD Australasia

It includes metrics like:

- Greenhouse gas emissions (carbon footprint)

- Energy and water use

- Resource depletion

- Waste generation

Why EPDs matter for steel products

- Supports Green Building Certifications

EPDs are often required or rewarded in Green Star, LEED, and Infrastructure Sustainability (IS) ratings. Using steel with an EPD can contribute to points under:- Materials transparency

- Embodied carbon comparison

- Life cycle assessment

- Enables Carbon Footprint Comparisons

EPDs allow comparisons between different steel products or suppliers, helping project teams choose lower-impact options. Care is required in understanding system boundaries and assumptions to determine if same measures are being used. - Builds Trust and Transparency

Because EPDs are third-party verified, they provide credible evidence of a product’s environmental performance—essential for ESG reporting and procurement. - Aligns with Regulatory and Market Trends

Governments and clients increasingly require low-carbon materials. EPDs help steel producers and fabricators demonstrate compliance and competitiveness. - Drives Continuous Improvement

By quantifying impacts, EPDs help manufacturers identify hotspots in their production processes and target areas for sustainability improvements.

What are key differences between SSA Level 1 and EPD?

Aspect | SSA Level 1 Certification | EPD (Environmental Product Declaration) |

Focus | Business-level sustainability and sourcing practices | Product-level environmental impact |

Scope | Covers governance, OHS, environmental management, and responsible sourcing | Covers life cycle assessment (LCA) data like carbon footprint, energy use, and emissions |

Applies To | Steel fabricators, processors, and suppliers | Specific steel products (e.g., beams, rebar) |

Standard | Based on GBCA’s Responsible Products Framework | Based on ISO 14025 and EN 15804 |

Verification | Third-party audit of company practices | Third-party verified LCA data |

Green Star Contribution | Recognized credits for Governance, Responsible and others for Buildings | Supports credits for Materials Transparency and Embodied Carbon |

Purpose | Demonstrates responsible sourcing and ESG alignment | Enables comparison of environmental performance between products |

Validity | Typically valid for 3 years with annual audits | Valid for 5 years or until significant product/process change |