Local Mills. Local Expertise. Australian Steel

Your trusted partner in steel manufacturing and supply

Local Mills. Local Expertise. Australian Steel

Your trusted partner in steel manufacturing and supply

Our certifications and credentials

At Orrcon Steel Manufacturing, we’re proud of our Australian heritage, and when we say we’ll see it through, we mean it.

Australian Made

Steel Pipe & Tube

As a leading Australian manufacturer of structural and precision steel pipe and tube products, we are committed to delivering quality, consistency, and flexibility. By partnering with us, you benefit from our dedication to excellence and our ability to innovate, supported by our in-house specialist expertise to meet your specific product or service needs.

We produce a wide range of structural and precision rectangular, square, and circular hollow section products. Every length of steel from our mills undergoes rigorous quality checks, with our quality management system certified to ISO 9001 and our testing facilities accredited to ISO/IEC 17025.

When you choose Orrcon Steel Manufacturing, you are assured that we will go the extra mile to “See it through,” ensuring a rewarding partnership.

STEEL PIPE & TUBE

Steel tube and pipe projects demand precision, consistency and reliability. That means partnering with a steel manufacturer with a proven track record and specialist knowledge to deliver exceptional results.

We specialise in manufacturing structural and precision RHS, CHS & SHS tube and pipe. Every length of steel that leaves our mills passes our quality management system which is certified to ISO 9001 and test facilities accredited to ISO/IEC 17025.

When you partner with Orrcon Steel, you are partnering with a steel, tube and pipe specialist that will deliver the quality products you need. Customer centricity is our number 1 priority.

watch now

Interactive Mill Tours

resources

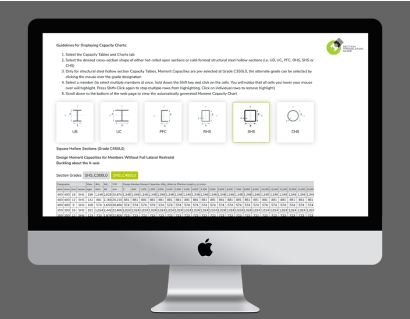

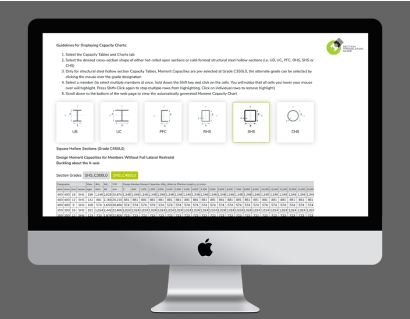

section translation guide (STG)

A resource purposed built to allow design engineers to evaluate and select structural steel hollow sections as suitable alternatives to hot-rolled open section steel design solutions.

section translation guide (STG)

A resource purposed built to allow design engineers to evaluate and select structural steel hollow sections as suitable alternatives to hot-rolled open section steel design solutions.

the orrcon steel difference

200+ Dedicated Team

We employ over 200 skilled people across Australia who use their steel industry knowledge and experience to produce and supply reliable steel products.

QUALITY PRODUCTS

Orrcon Steel’s Quality anagement System meets the highest standards and quality assurance to comply with the requirements of ISO 9001.

AUSTRALIAN MANUFACTURING

Orrcon Steel has three Australian manufacturing sites – Brisbane, Wollongong & Adelaide.

case studies

building for the future

Our structural tubular products are a significant part of our production and are used across a wide range of structural applications from building structures to major sporting arenas, major mining and industry infrastructure and for aesthetic structural use such as airports and shipping terminals. Orrcon Steel’s precision products are manufactured to comply with AS1450.

Whether it’s specialised tight tolerance, high bending quality Precision Tube, corrosion resistant in-line Electro Galvanised ALLGAL Tubulars (with Zinc both inside and outside the Section), or high quality fire pipe that passes through multiple check points to ensure end users can be confident there will be no leakage from this important tubular product used in fire safety systems. Every length of steel that leaves our mills passes our quality management system which is certified to ISO 9001 and test facilities accredited to ISO/IEC 17025.

our in-house laboratory facilities

Orrcon Steel operates the National Laboratory which is accredited to ISO 17025 by NATA. Accredited since 2009, the laboratory located at Orrcon’s head office in Brisbane undertakes grade certification to AS/NZS 1163 and quality assurance testing. The full scope of accreditation includes the complete range of mechanical testing required for structural pipe and tube, including: tensile test, hardness, impact resistance, flattening and macroscopic examination. The chemical analysis of low alloy and plain carbon steel is also included in the NATA scope, which allows for the chemical analysis of steel products and compliance to weldability and batch galvanizing requirements.

The laboratory is equipped with a workshop containing bandsaw, CNC milling machine, linisher, broaching and metallographic sample polishing and etching equipment. The Laboratory team provides additional technical and product development services to our manufacturing and sales team through technical expertise: including X-ray fluorescence, non-destructive testing, coating mass and humidity testing.

our in-house laboratory facilities

Orrcon Steel operates the National Laboratory which is accredited to ISO 17025 by NATA. Accredited since 2009, the laboratory located at Orrcon’s head office in Brisbane undertakes grade certification to AS/NZS 1163 and quality assurance testing. The full scope of accreditation includes the complete range of mechanical testing required for structural pipe and tube, including: tensile test, hardness, impact resistance, flattening and macroscopic examination. The chemical analysis of low alloy and plain carbon steel is also included in the NATA scope, which allows for the chemical analysis of steel products and compliance to weldability and batch galvanizing requirements.

The laboratory is equipped with a workshop containing bandsaw, CNC milling machine, linisher, broaching and metallographic sample polishing and etching equipment. The Laboratory team provides additional technical and product development services to our manufacturing and sales team through technical expertise: including X-ray fluorescence, non-destructive testing, coating mass and humidity testing.

PART OF THE AUSTRALIAN LANDSCAPE SINCE THE 1960’S

AUSTRALIAN MANUFACTURED PIPE & TUBE

Orrcon Steel was formed from the merger of Welded Tube Mills and Hills Tubing division in October, 2000. It traces it’s manufacturing roots to Hills Holdings, manufacturer of the iconic Hills Hoist in the 1960’s. In February 2014, BlueScope Steel acquired Orrcon Steel from Hills Holdings.

We are now a wholly owned subsidiary of BlueScope Steel Ltd. BlueScope Steel is an Australian steel manufacturer with operations in Australia, Asia, New Zealand, North America and Pacific Islands.

REQUEST MORE

INFORMATION

When you contact Orrcon Steel for advice or assistance

you get to the right person with the right answers.